As promised here is the second installment of the ‘Guys from Texas’ room. Below are mini-tutorials of how I made some of the Christmas Greenery for the room.

Greenery Sprays (including one with stocking hooks)– There are two sprays, both made very similarly. One above the mirror (see photo above) and another on the mantel. For both I started with very narrow wire greenery sold on spools at Hobby Lobby (see second photo below). I made the base form by cutting and shaping the stems.

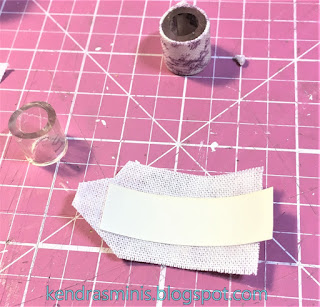

For the mantel one, to make it removable, I glued the greenery to pieces of plastic cut from grocery store clear plastic spinach cartons. I glued the greenery and some wire stocking hooks with Quick Grab glue.

I thought the greenery was too dark so I lightened it by brushing on a mix of lighter leaf green and metallic green.

To the base greenery shape I added snips of artificial pine needles bundled together with glue.

Added small glue dots (using very fine glue applicator) and sprinkled with red glitter for “berries”.

Holly Leaves – cut from green paper using scrapbooking holly leaves punch. Edged with light green paint and scored a vein down the middle with the back of an X-Acto Knife.

Placed a few of these leaves among the greenery then added ornaments (glittered beads).

That's it! The stocking greenery just sits on top of the mantel and can easily be removed. The hanging one above the mirror is held on with blue-tac and removed after Christmas. Next blog I will cover how I made the removable vase fillers in the ceramic vases from silver beads and sprigs.

Well, I have achieved one goal this year - to do one blog post a month (well, actually I skipped a couple and doubled up to make up for it but STILL that is 12 posts for one per month AVERAGE!) Whew! Hope my readers have a wonderful New Year in 2020!